I have friends who keep their sewing machines in a closet and it’s not because they don’t want to sew. They do. It’s just that sewing on their machines can be frustrating. They wonder if their machine needs fixing, or if they bought a bad machine.

Probably neither.

Sewing machines are pretty straightforward, mechanical tools. (Except for the computerized machines, but even then the sewing mechanism works the same.) The frustration with using them is simply a little missing knowledge.

This video shows and explains 11 tips to reduce your sewing machine frustration and get the best out of your sewing machine.

Get that machine out of the closet and start enjoying all it can do.

The Summary

Watch the video for full explanations

1. Get to know your machine.

2. When threading your machine make sure the presser foot is up.

3. At the end of any sewing check that the thread take-up lever is up.

4. Replace your needle often.

5. Clean your machine of lint after every project.

6. Oil your machine more often than you think. (To be certain no oil will transfer onto your next project, sew on a scrap of fabric or a folded paper towel after oiling your machine.)

7. Bring up the bobbin thread manually even though your machine may do so automatically.

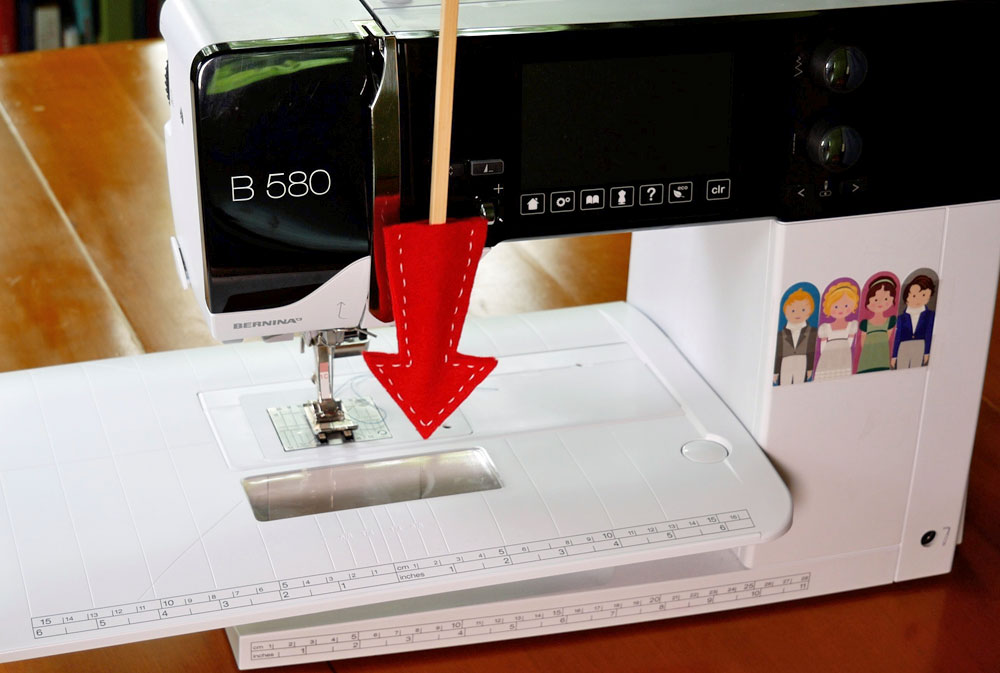

8. Clear the plate before you begin to sew.

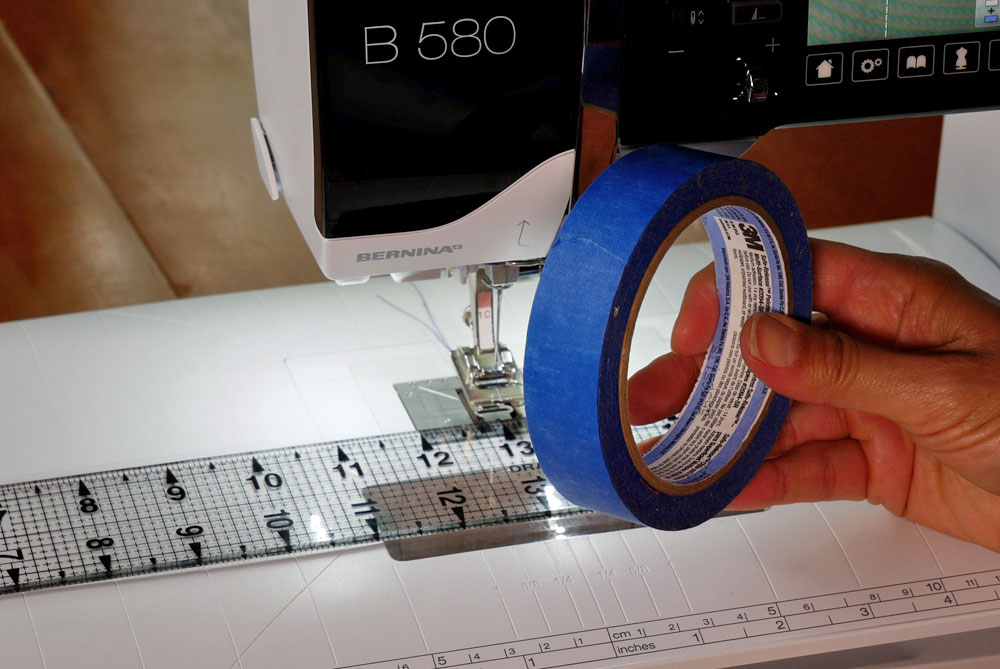

9. Use painter’s tape to make extra wide sewing guides.

10. Never wrap the cord around the foot pedal.

11. Put the presser foot down when moving the machine

If you have any tips you want to share, please do. We all enjoy a good tip.

Thank You, Thank You, Thank You. I have 4 sewing machines of which only one is useable. I have a Singer Heavy Duty (working), Brothers, Pfaff and a Singer Commercial Zig Zag. I also have a Montgomery Ward 21 Jewel Supreme Zig Zag from early 50’s that works on occasion and a Singer G2252276 same era that doesn’t work. Any instructions, suggestions and information will be greatly appreciated. I’m thrilled just having a straight line work without problems – so I am looking forward..

I only know the basics of how sewing machines work so I can’t think of any more advice for your machines, unfortunately. I do know having them checked out and serviced by a reliable sewing machine repair person is worth the hassle and money. Good ones can find the true source of the problem, like a loose something-or-other in my old Pfaff (thanks, mom) that was the cause of all the problems that machine was having.

The bad news though is that not all the parts are being made for the old machines anymore. They rather sell you a newer machine than a part to fix your old one. So find a crafty repair person who might be able to MacGyver your machine if needed. And the Great news is that a straight stitch is the stitch you will use for 95% of your sewing (not scientifically researched 🙂 The other little bit can be done by hand.

How did you get so many machines? Maybe the old singer could be used for parts to fix the Montgomery Ward machine. I think Singer made the Kenmore machines so it’s possible they did the Montgomery Wards too. I wish you luck in getting them all up and running. Sorry I couldn’t help more.

Knowing when to change the needle, I only way I can think of a way is to log when you sew and for how long, if you sew regularly then it won’t be long before you need to change your needle and make sure that you have the right one for the right tasks

I still struggle with knowing when to toss a needle and when to keep sewing with it. A simple notation on a post-it or in a notebook, like you suggest would probably be the easiest. I recently thought, what if I took a scrap of fabric from the project and used the needle that was used to sew the project to pin that scrap to a corkboard? Then I would know about how many hours I used it last and how much more I can use it. But a log is simpler. I need to stop overthinking it.