Let’s talk about sewing machine needles. As far as sewing tools go they aren’t trending or cute. They’re probably more of an afterthought – meaning you’ve selected the pattern, fabric, thread, and buttons, and didn’t even think about a needle. People, the needle is one of the most important parts of a sewing machine. Without it, sewing would not be possible.

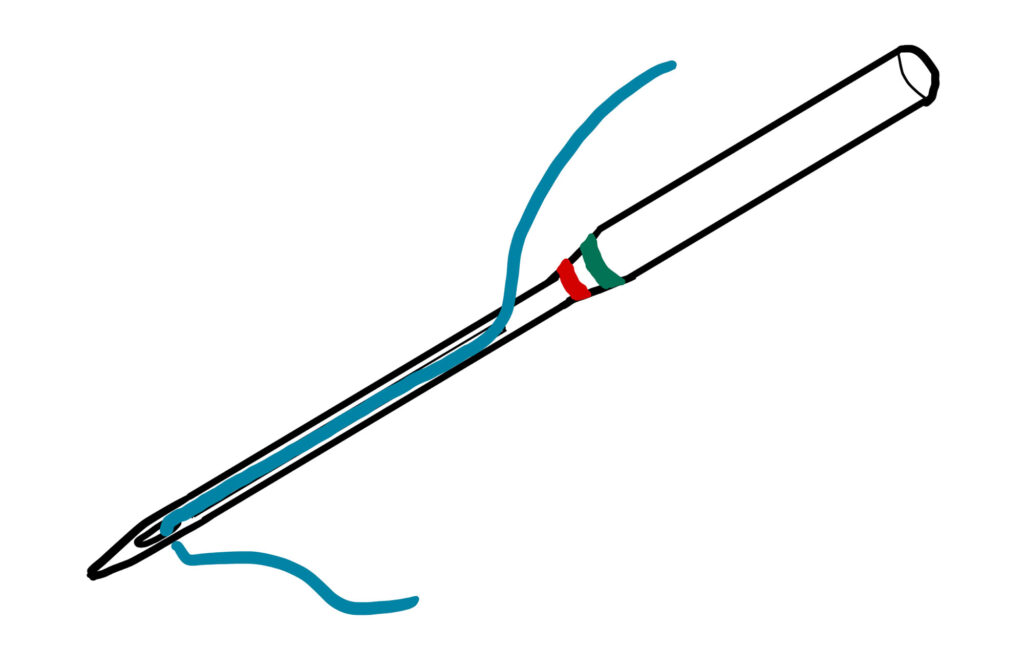

The needle is tasked is to penetrate the fabric, and form a small hole through which it will guide the thread. Under the needle plate, the needle will support the thread as the looper/hook brings the bobbin thread up and through the small thread loop, form a stitch

And it will do all of this at some amazing speeds which is why using the correct needle can make a huge difference in the quality of your stitches.

Buying the correct needle starts with knowing which needle system your machine needs. Then what type and size your fabric needs.

Becoming familiar with the common types and sizes of needles, the mistakes to avoid when it comes to machine needles, and the signs that you need a new needle might make the difference between a project well sewn or a project ruined.

Watch here or read on (FYI: this blog post contains more detail than the video)

Anatomy of a Needle

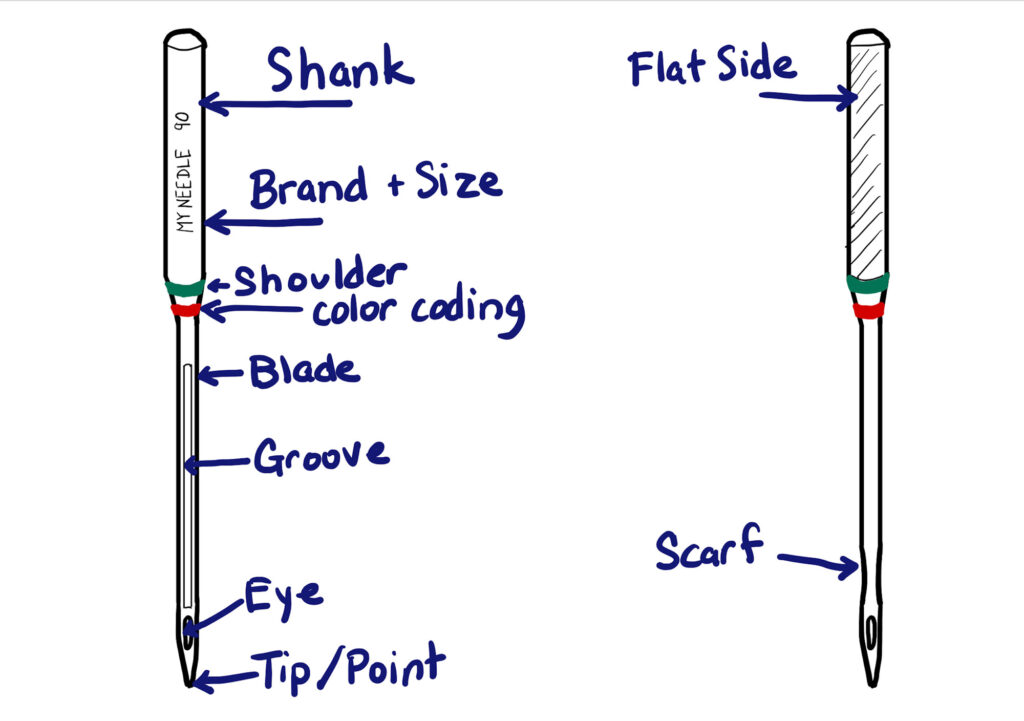

Parts of the needle (frontside):

- Shank – The shank is the upper section of the needle that is inserted into the sewing machine. On domestic sewing machine needles, the back of the shank is flat. On industrial machine needles, the shank is round.

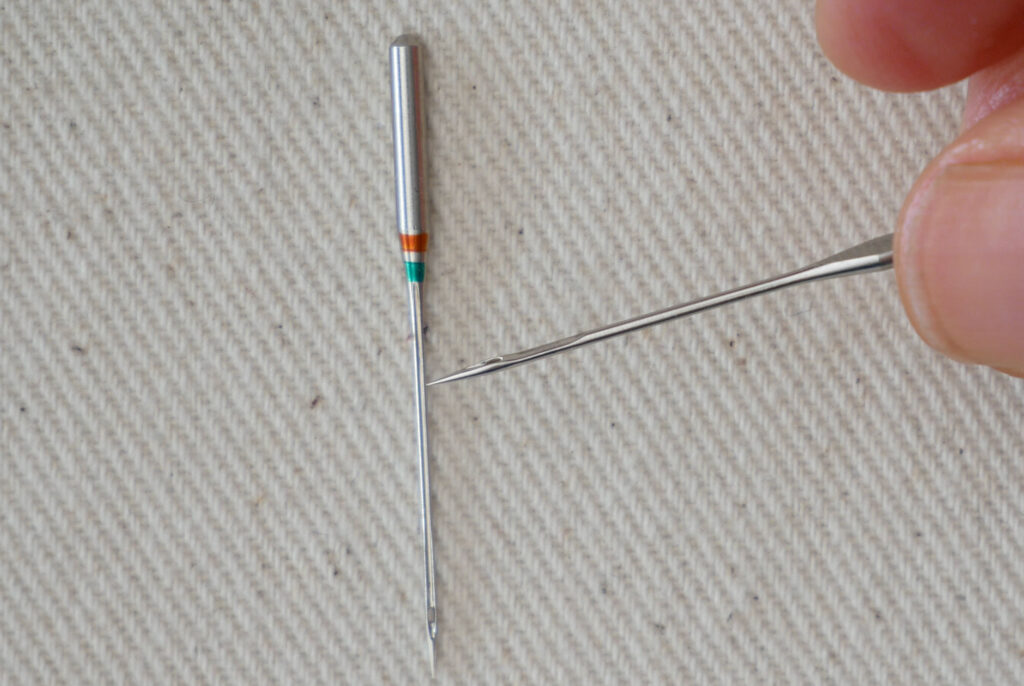

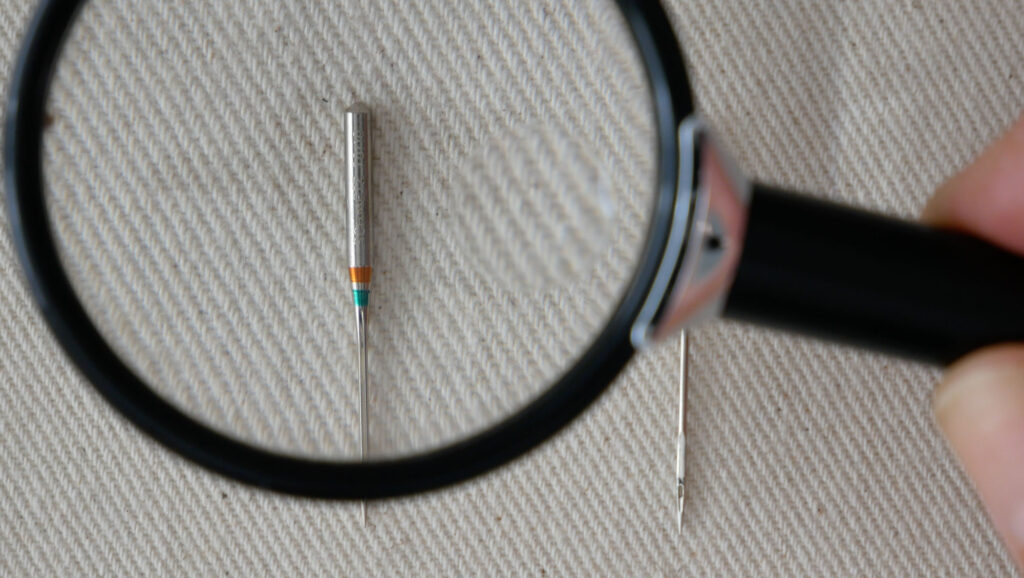

- Brand and Size – The brand and size are often etched into the shank though you may need a magnifying glass to read it

- Shoulder and color coding – The shoulder of the needle is the transition between the thicker shank and the thinner blade. On the shoulder, some brands add a color code to help you identify the type and/or size of the needle.

- Blade – The long narrow part of the needle is called the blade or shaft. The width of the blade varies and determines the size of the needle.

- Groove – There is a long groove in the blade above the eye. This groove is where the thread will tuck into when the needle passes through the fabric to reduce friction and form the stitch. The groove’s size and length change with the needle’s size and type.

- Eye – The eye of a sewing machine needle is near the point, which is opposite to where the eye of a hand sewing needle is. The eye is the hole that the thread goes through when you thread your sewing machine and it will vary in size depending on the type of needle.

- Tip or Point – The dangerous end of the needle is the sharp tip or point. Different shapes of the tip: sharp, angled to cut as it stitches or slightly rounded (but still sharp) are designed to be used on different fabrics.

On the back of the needle:

- Flat side – The shank of domestic machine needles will have a flat side. It has become most common for the flat side to be facing away from you when inserting the needle into the sewing machine but some machines will place the flat side to the right so it’s very important to know your machine!

- Scarf – The scarf is an indent or hollow area above the eye of the needle. It allows the bobbin hook or looper to get close to the needle as it rotates by to grab the needle thread and form the stitch.

The Three Main Things You Need to Know to Choose the Correct Needle: System, Type, and Size

Needle System

Every machine is designed to work with a specific type of needle system also referred to as needle class. The system stands for the diameter and shape of the needle shank, and the length of the needle.

The manufacturing industry has many specialized “sewing” machines. Industrial sewing machines, blindstitch machines, overcast machines, buttonhole machines, sewing Automats, and more. Each machine is designed to hold a specific shape, diameter, and length of needle. Or, another way to put it each type of machine is designed to work with a specific needle system.

As sewing machines were being introduced for home use around the world, each manufacturer had their own distinct needle system for their machines.

Luckily almost all domestic sewing machines now use a common needle system. However, some domestic sergers/overlock and coverstitch machines use a different system. Check your manual.

The name of the needle system will vary by producer and it’s the first number you see on the needle packaging. The needle system 130/705 is equivalent to 15×1 H needles which is Japanese, the HAx1 system, and Singer’s 2020 system. (Pre 1970 the Singer needle system was named 15).

These systems all have a flattened shank for perfect positioning of the needle in the machine and are available in different standardized shaft diameters suitable for sewing different fabrics.

Some older machines may take a different needle system/class. Especially Singer sewing machines. Singer needles use to be slightly longer than other brands. Always check your manual to see what needle system it uses.

If you acquired your machine secondhand and do not have the manual an online search will bring up .pdfs of manuals for sale or perhaps you can find a copy in the Internet Archive’s Way Back Machine https://wayback-api.archive.org/ for free.

Needle Type

Needle Type refers to the type of point the needle has. Select a needle type for the job you are doing and the type of fabric you are sewing.

There is an alphabetic code for the point types and sometimes it is shown on the package for example a ballpoint tip will have the code: SES, and a needle designed for embroidery has the code H-E. So unless you have a cheat sheet handy I go by the words. If you are using an industrial machine you’re going to need that cheat sheet.

Many brands use a color code for the needle type but the code varies by brand. The top band of color on Schmetz needles indicates the type of needle it is

Common types of Needles

- Universal (code SES) – The universal needle is designed to be used on most fabrics – hence the name. The tip of this needle is slightly rounded and the longer scarf is designed to prevent skipped stitches.

- Jersey (code SUK) – Designed for sewing knit fabrics, these needles have a more rounded tip than the universal needle to slip between the knitted loops that make knit fabric without cutting the loops or making a puncture that would cause a run in the fabric.

- Stretch or Stretch Ballpoint (code S or SS) – This needle is for highly elasticized fabrics like spandex, or lycra. The shorter eye and a deeper scarf prevent skipped stitches.

- Topstitch (code N) – Topstitch needles have an extra long eye and a deeper groove to accommodate the thicker topstitch thread.

- Jean (code J) – This tip is designed to sew densely woven fabrics like denim, canvas, upholstery and twill.

- Microtex (code M) – The Microtex point is very sharp and is designed for synthetic fabrics like polyester, nylon, micro cloth and vinyl because synthetic fibers can wear down a needle pint much quicker than natural fibers. But this needle is also good for bamboo fibers, cork, waxed cloth and sequins.

- Leather (code LL or LR) – This tip is designed for cutting. Use it for leather, suede and artificial leather.

- Metallic (code M) – when you stitch with metallic thread you need a metallic needle. It makes this hard to work with thread a lot easier

- Quilting (code Q) – Quilting needles are designed to penetrate many layers of fabric without making a large hole. Because, even though there are many layers, none of them are particularly heavyweight

Needle Sizes

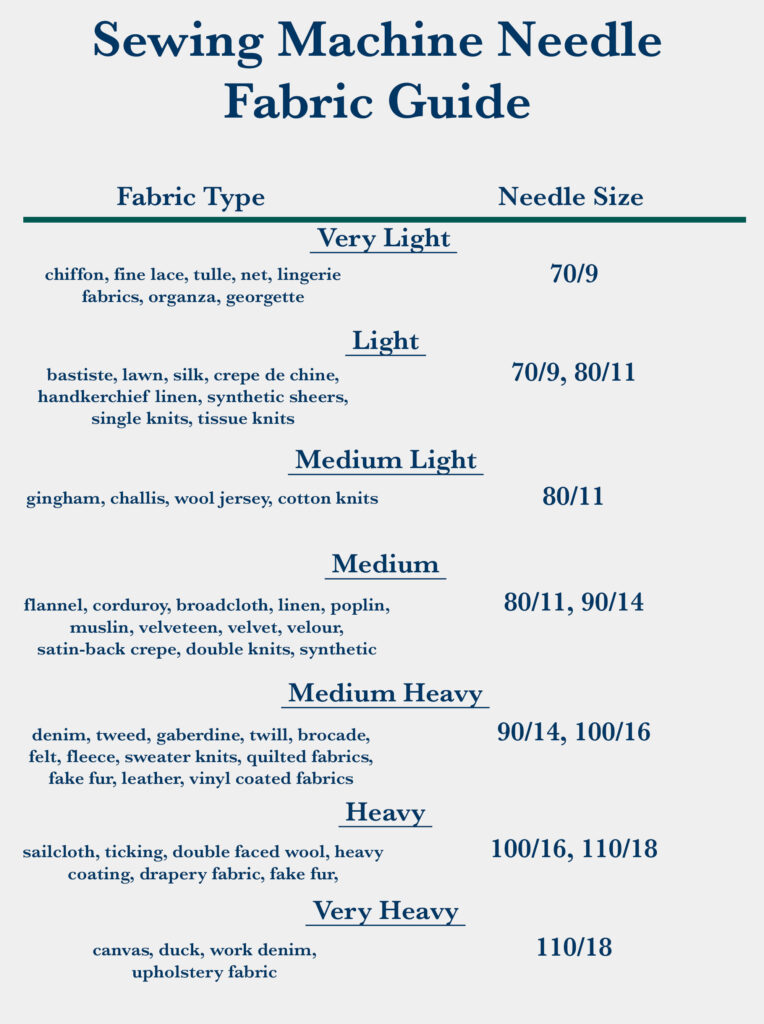

You will notice, on most needle packs, two numbers representing the needle size. The higher number is the European or metric size telling you the diameter of the blade. The lower number is the imperial sizing system. These two numbers can be shown in either order for example; 110/18 or 18/110.

Conveniently both systems’ numbers go higher as the needles become thicker and stronger. A size 65 is a thinner needle, and a size 90 is for midweight fabrics.

More conveniently, many brands now use a size color code on their needles. However, the colors vary by brand.

These needles are all size 80 but are different types of needles. The top color band represents the type of needle it is. Universal needles do not have a color band to represent type. You can view Schmetz’s color coding chart on their site.

The needle size is also etched into the needle’s shank.

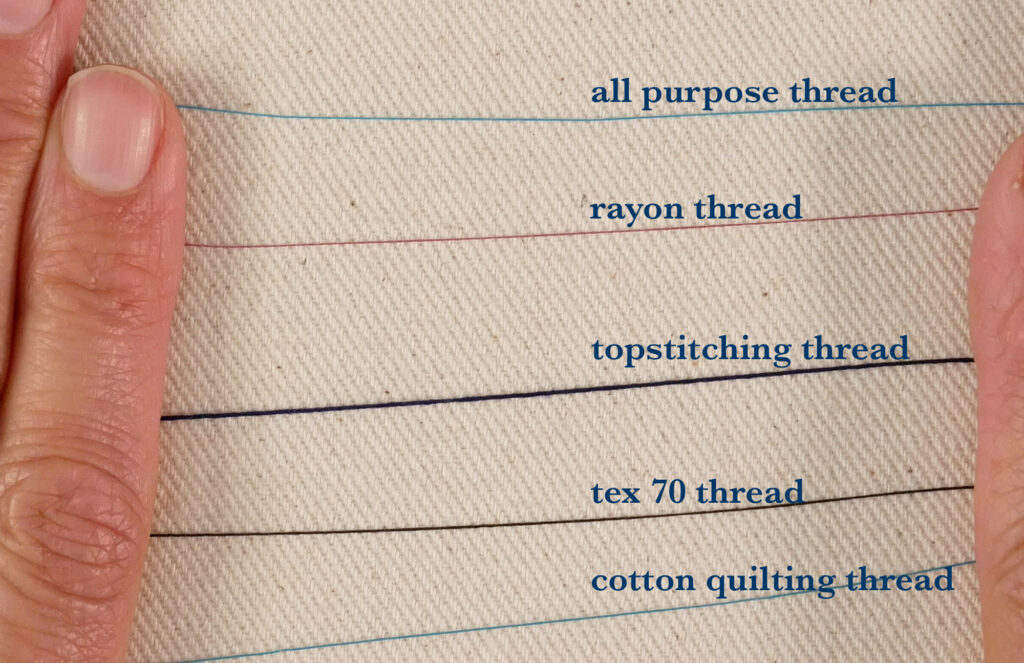

Selecting the proper needle size depends on the size of the thread and the fabric weight.

Most of us home sewist use limited types of thread: all-purpose, topstitching/heavy-duty, and cotton thread. So we are used to picking the needle size only by the weight of the fabric we are sewing. Which works 9 out of 10 times. But on that project where the thread is fraying, becoming damaged or breaking or you’re seeing skipped stitches try changing your needle to one size up or down.

The thread thickness matters because it has to fit in the needle’s groove, So it’s not just fabric weight but also the thread when selecting the right size needle

The needle should be just large enough to go through the fabric without bending. A needle that is too large can cause fabric distortion, puckering and skipped stitches.

Low number sizes equal fine needles for delicate and lightweight fabrics. Sizes that are high numbers are for thick and tightly woven fabrics.

Buying Needles

Needles typically come in packs of five. For convenience, you can buy a pack of needles in assorted sizes. You can also find universal needles in packs of ten.

Not all types of needles come in all sizes.

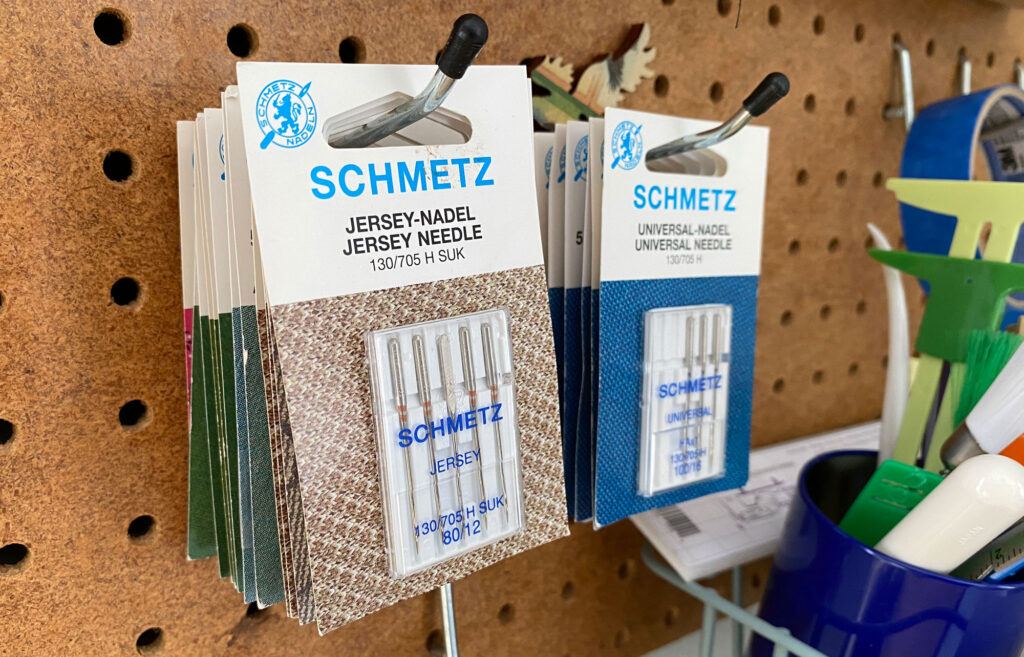

My favorite sewing machine needles are Schmetz (probably obvious by now)

The product linked above is an Amazon affiliate link. I buy, use and recommend Schmetz needles. You can buy them from anyone but if you purchase through the above link I receive a tiny percent back from Amazon which helps to support this channel. Just letting you know 😉

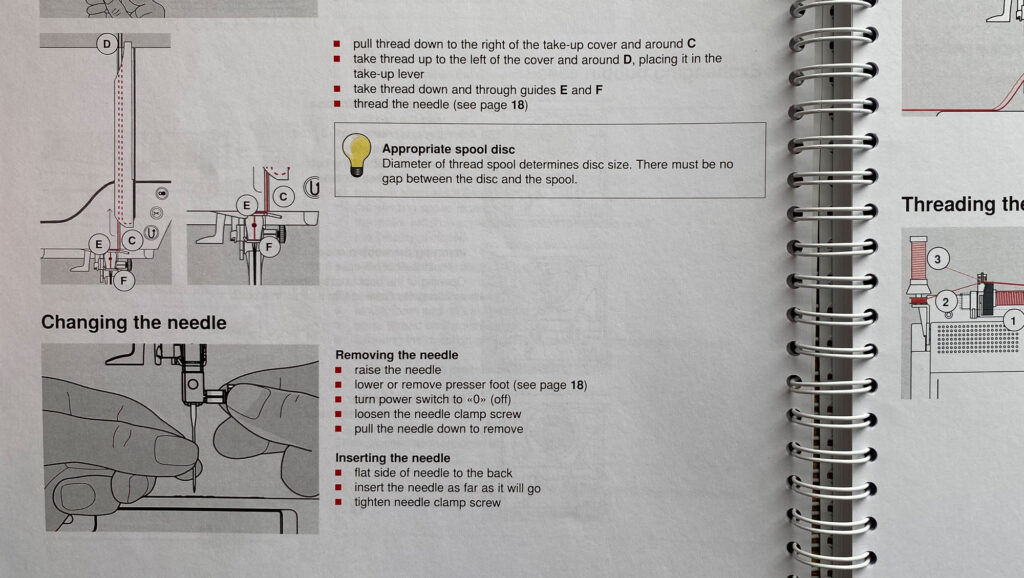

Inserting Needles

How the needle is inserted into the machine, in which direction the flat side and the eye face can vary by machine. Check your manual. It’s important to be sure the needle shank is inserted all the way into the machine. A needle inserted incorrectly can damage the machine.

When to change the needle

This is the number one question we all want to know. Unfortunately, the answer is, “it depends”.

Typical advice is to change your needle after it has been used for 8 hours or every 2 to 3 projects. Ok, that sounds easy but it’s hard to keep track of how many hours you’ve used a needle especially if you often switch between projects (and needles). And nobody wants to toss something that’s still useful.

So here are some tips for when to change your needle

- Synthetic fibers wear down a needle quickly. This includes spandex, polyester, nylons, and synthetic blends like cotton/poly, wool/poly, and wool/nylon. Discard the needle after completing a project using synthetic fibers

- Change your needle after sewing over a pin. (You know, when you sew over one and it makes a crunch sound – that’s a sure sign some damage was done)

- New topstitching needles should be used for a garment with high contrast or prominent topstitching.

- In the middle of a project replace the needle if:

- you notice skipped stitches and nothing else has changed with the current project.

- if the thread starts jamming.

- you notice damage to the fabric.

Needles are relatively inexpensive to replace and can make a big difference. Note: although it is rare, a new needle can be defective out of the packaging and will need to be tossed before you can sew 8 hours with it.

Important PSA

When you discard sharp objects do it with respect to any person, or animal that will come across it later. Collect discarded needles, bent pins, and dulled Xacto blades in a lidded container to be tossed when full or place a piece of tape over the sharp point to cover completely before disposing.

Remember

Most stitching problems are caused by needles that are the wrong size, damaged, or inserted incorrectly. Changing the needle may make all the difference and it’s quick to check to see if it will.

Mary, I just watched your thorough video on the details of a machine sewing needle. It was fabulous. I want to ask you if you would be interested in my little invention the Needle Noter. It is a labor of love by a sewist who, rather late in life, decided to invent a notion that would eliminate the frustration that comes from not remembering which needle was last placed in a given machine. Please look at my website http://www.needlenoter.net If you’re interested, I would be very happy to send you one and perhaps you could share its purpose with your viewers, Just tell me where to send one.

That’s a clever notion you have come up with. I can totally see how useful it is.